Six Sigma White Belt Certification Exam Questions and Answers

Six Sigma White Belt Practice Test-Free Sample Questions and Answers

The Six Sigma White Belt practice test is a free assessment tool designed to evaluate your understanding of fundamental Six Sigma concepts. It includes multiple-choice questions on topics such as process improvement, waste elimination, DMAIC, and basic statistical tools. This test serves as an introductory step into the Six Sigma methodology, helping individuals become familiar with core principles and the roles involved in process improvement teams. Scoring well in this test reflects readiness to participate in real-world quality initiatives and lays the foundation for higher-level Six Sigma certifications.

If you're preparing for the exam, reviewing Six Sigma White Belt certification answers can help you identify areas where you need improvement and boost your confidence.

We also provide Six Sigma White Belt exam answers to guide learners through commonly asked questions and reinforce key concepts before taking the actual certification.

1. Which of the following is the main feature of MSA (Measurement System Analysis)?

a) It helps to measure the system of continuing production.

b) This is the method of analyzing accurate measurement system.

c) This method is used for the purpose of block measurement.

d) None of these.

Measurement System Analysis is the process of verifying or properly analyzing the data collected from measurement and inspection of various companies.

2. Which among the following is true about Process Capability Index (PCI)?

a) This is the process of calculating gross production capability of a company.

b) This is an index, which shows the least production ability of a process.

c) An Index, which shows the capability of a process for sufficient production.

d) An Index, showing the target production of a process.

Process Capability index shows the capability of a process that it can produce sufficiently as per the requirements within the limited time.

3. What is an EWMA (Exponentially Weighted Moving Average) Chart?

a) It is a Control Chart.

b) It is a Measurement Chart.

c) It is a Growth Chart.

d) None of these.

An Exponentially Weighted Moving Average Chart is a control chart which monitors any business’s entire history of output. It uses variables or attributes - type data.

4. The chart is used for rearrangement of time, when any change is detected in a process.

a) IPWA Chart

b) CWMA Chart.

c) EWMA Chart.

d) CUSUM Chart.

CUSUM Chart is used to detect changes in any process. This chart is generally used for identifying the change and rearrangement of time to fulfill the requirement of production.

5. What is the method of ACCEPTANCE SAMPLING used for?

a) This method is used for new product sampling.

b) The method includes acceptance and rejection of products by inspection.

c) To make a nonconforming product conforming this method is applied.

d) None of the above.

ACCEPTANCE SAMPLING method is used at inspection of products to identify the good and bad items within the lots and also accepting and rejecting the products.

6. What is an OC Curve in sampling process?

a) A diagram representing the probability of acceptance for a lot.

b) A curve which indicates the percentage of bad quality products in a lot.

c) A diagram which indicates the rate of production per day.

d) None of these.

An OC Curve is a diagram which shows the probability of acceptance of a lot in sampling process.

7. Which of the following statement is true about LTPD (Lot Tolerance Percent Defective)?

a) LTPD is the collected data which shows the defective products in a lot.

b) LTPD represents the company’s loss for producing defective products.

c) This is the method of calculating the percentage of accepted and rejected products.

d) LTPD is the lowest quality of any product that can be accepted.

Lot Tolerance Percent Defective is the lowest quality of any product that can be accepted while sampling. It has a 10% chance of being accepted.

8. Which of the following is used to select the process of sampling plan?

a) DODGE ROMIG Table.

b) AOQL ANSI Table.

c) ATI & LTPD Measures.

d) None of the above.

DODGE-ROMIG table is used for the purpose of selecting plans for sampling process. The table uses AOQL & LTPD measures for selecting plans.

9. The data that can be counted only in whole numbers is called what?

a) Decreased Data.

b) Attribute Data.

c) Variable Data.

d) Continuous Data.

Attribute Data is the data, which can be counted only in whole numbers, as half of a customer cannot be counted.

10. Why Pareto chart is important in six sigma?

a) It gives the appropriate figures of employee’s performances.

b) It suggests a company of its variances in focus.

c) It provides the company production rate variations.

d) None of the above.

Pareto chart is famous for its 80/20 theory. In six sigma it is also important, as it represent a company which subject is extra focused and which subject need to be focused more.

11. FMEA is a tool in six sigma, which is:

a) A tool for calculating the measures of risk or failure in a process or a system.

b) A tool for understanding the loss of funds in a process, which is going to fail.

c) A tool, which measures the ratio of percentage loss and profit of s company.

d) All of the above.

Failure Mode Effect analysis is a tool to measure the risk of a process or a system failing to produce as per the requirement and then working on the problem to overcome.

12. What do you understand about COPQ in six sigma?

a) Cost of producing quality.

b) Cost Of Poor Quality.

c) Cost Of Processing Quality.

d) Cost Of Preparing Quality.

Cost of Poor Quality is the cost caused through producing defects.

13. Explain FMEA in six sigma belt?

a) FMEA is a spreadsheet data of risk factor of a working process to help the team.

b) FMEA is a data of measurement of any process related with production.

c) It is a factor of the production process, which indicates reliability.

d) It is one of the most commonly used statistical process control procedure.

FMEA is generally a spreadsheet data chart or can be called as a tool for calculating the risk factor of any process for failing

14. What is the 1.5 sigma shift?

a) The 1.5 sigma shift is the process of collecting data of every cycle for identifying difference.

b) It is the numerical tool of six Sigma.

c) It is used for measuring the customer requirements.

d) It is the producing unit of six Sigma.

The 1.5 sigma shift is the process of collecting data of any process in many cycles of manufacturing, whether it has a difference.

15. Which of the following facts are true about X-bar and R charts?

a) These are the two charts of monitoring the behavior and the outcome of any process.

b) This is a tool for starting up the Six Sigma.

c) This two chart is used for counting the total manufactured products and the total requirement of manufacturing.

d) It is used for the production of process report in Six Sigma.

This is a set of chart, which is the most important factor of process control, they include the inspection of behavior and outcome of any process of manufacturing

16. What is the Pareto principle?

a) It is the 80/20 rules in six sigma belt, in most of the cases, 20% of the effect comes from the 80% of the causes.

b) It is the 90/10 rules in Sigma Belt.

c) It is used with continuous measuring in Sigma Belt.

d) It is one of a different kinds of variation use in six Sigma.

The pareto principle states that for most of the cases 80% of any effect is caused from 20% of the main reason. This principle is worlwide accepted at present.

17. What are the main variations of six sigma?

a) mean, median, range and mode.

b) DPPM and COPQ

c) Pareto principle and R charts

d) Only mean and median

mean, median, range and mode are the are the main variations in six sigma.

18. What is standard deviation?

a) It is a measuring process to measuring the average spread of data.

b) This is the process of deviation.

c) It is a process capability index.

d) It is the process of calculating the difference between customer requirement and production.

Standard deviation dictates the degree of variation of a process or in any measurement, by measuring the spread of data.

19. What does Cpk means in six sigma belt?

a) The process Capability index.

b) The process of calculating data of a process.

c) It is a diagram, which shows the production capability of any process.

d) None of the above.

Cpk is the process Capability Index, which indicates the fulfillment of any process’s specied limits.

20. What is Ppk in six sigma belt?

a) It is a measuring process to measuring the average speed of production.

b) It is a diagram displaying the sequential steps of an production.

c) It's term is used for measuring the data of employee perfomances of a company during a year.

d) This is the index of the performance of a process.

Ppk is the index, which dictates the performance of a process, whether it has came over the customer'sneed or not.

21. What is flowcharting in sigma belt?

a) It is a diagram, which displays the steps of a process.

b) It is a chart, which shows the total production rate of a process.

c) It is a chart of production in six Sigma.

d) It is a measuring process to measuring the average spread of data.

Flowcharting is used as a diagram, which displays the steps sequentially of any process or workflow.

22. What is brainstorming in six sigma belt?

a) It is a technical method in six Sigma.

b) This is the process of Problem Solving.

c) it is a procedure of suggesting ideas about a problem in a process by a group discussion or a meeting.

d) It is a qualitative and systematic tool.

Brain Storming in six sigma is used as a process to create an extraordinary idea within a short period of time to solve any problem. Or it can be called as quick problem-solving method.

23. What is regression?

a) It is a procedure used to monitor process behavior.

b) Regression is used for establishing the relationship between input and output variables.

c) It is an output variable set of six Sigma.

d) It is a defined relationship between x bar and R charts.

Regression Analysis is processed to establish the relationship between the sets of an output variable and an input variable.

24. What is fish bone/ishikawa diagram?

a) it is categorizing measuring problem in six Sigma.

b) It is a only identify root causes.

c) It is a qualitative and systematic tool.

d) It is categorizing the potential causes of a problem.

Fish Bone is the process of begetting the potential cause of a problem, according to which we can reach at the root of the problem.

25. What is process report?

a) it is a reporting system which gives processing report.

b) it is a process of production in six Sigma.

c) It is a technique used to define the structure of six Sigma.

d) It is the process capability report.

Following a Belt Curve Distribution, process report shows the capability of any process.

26. Which of the following is correct about Product Report?

a) It is a production tool of six Sigma.

b) It is used to displayed data.

c) it is a procedure used to monitor the performance of a company.

d) It is a discrete data.

Product Report is a discrete data consisting with performance metrics of any process

27. What is six sigma DMAIC?

a) It is a measuring tool in six Sigma.

b) it is a procedure of starting up with the sigma belt.

c) It is applied discrete data.

d) This is the quality initiative of six sigma.

DMAIC is the 5 step quality initiative of six sigma, as Define, Measure, Analyze, Improve, & Control.

28. Who introduced Six Sigma Belt?

a) Bill smith.

b) William Smith.

c) Jack Welch.

d) Matthew Boulton

Bill Smith in 1986 has first used the term and invented the famous method of six sigma.

29. Who is made six sigma belt central to his business strategy?

a) Bill smith.

b) Matthew Boulton.

c) Jack welch.

d) William smith

Jack welch of General Electric, made it central to his business strategy in 1995.

30. Which company registered six sigma belt as trademark ?

a) Motorola.

b) Lenovo.

c) Apple.

d) Blackberry.

In December 28, 1993 Motorola registered six sigma belt as a trade mark.

31. What is the use of ANOVA in Six Sigmas?

a) ANOVA is a method of calculation.

b) It determines the means of various continuous data.

c) Both of the above.

d) None of the above.

ANOVA is the process of determining the different means of various continuous data, which helps to differ one group from another.

32. Which of the following is true about Shewhart Chart?

a) This chart is made for determining the growth of a company

b) It shows whether the process of a business is reliable or not.

c) It represents the growth of the process of any business.

d) None of the above.

Shewhart chart is a control chart which shows the process of a business is in reliable condition or not.

33. Which of the following is true about Simple Random Sampling.

a) Simple random sampling is a method of chosing samples randomly from an infinite population.

b) This is the process of sampling, which includes collecting various samples randomly from one or more groups.

c) In this process a company gives a random sample of its production for being approved as a sample.

d) None of the above.

Simple Random Sampling is the Sampling Process where a simple random sample is taken to be inspected from a large group.

34. What should be the main characteristic of a process to achieve a six sigma?

a) A product should possess all the best quality measures to achieve a six sigma.

b) A process should not produce more than 3.4 defects in a million, to achieve the six sigma.

c) A process should not contain more than 5.5 defects, to achieve six sigma.

d) None of the above.

Six sigma certification is produced to a process when it is proved not to be producing more than 3.4 defects.

35. What is an Activity Network Diagram in six sigma?

a) This diagram shows the whole employee’s activity of a company during an year.

b) This diagram shows the progress of the networking process of the company.

c) This diagram shows the farthest and closest expected time of completion of a project.

d) All of the above.

Activity Network Diagram is used create an idea of completion of a project within an optimistic and pessimistic time period. This method clearly indicates the time period of a project.

36. Which of the following is / are true about Chi-Square Test?

a) This is a part of Statistical tests.

b) This test is a quality test for any production.

c) None of the above.

d) Both of the above.

Chi-Square test is a statistical test tool for determining the dependence and independence between different variables taken from different groups.

37. What is Inferential Statistics in six sigma?

a) This is the method of determining process capabilities.

b) This method shows the statistics of the process.

c) This method shows the process of production.

d) None of the above.

Inferential Statistics shows the capability of a process by determining all the means. It calculates from machine to manual operations and raw materials to determine the actual capability of the process.

38. Which of the following is true about Nominal scale?

a) This a measurement scale which lists names in alphabetical order.

b) This is scale which includes data of names of the product of any company.

c) This is scale of listing the names of the industries within a metropolitan cities.

d) All of the above.

Nominal Scale is a measurement scale which lists the names in alphabetical order, though there is no particular orders of the names.

39. Which of the following is correct about DMADV

a) This is the process for determining the quality of the product, which is ready to deliver the customer.

b) This is the method of making a new process of business.

c) This method is used for making new product’s sample.

d) DMADV is the measure of using new process for production.

DMADV is the method for creation of new process of production while remembering the quality and demand of the customer need to be kept same.

40. Form, Storm, Norm, Perform, these are the stages of:

a) Likely phases a team goes through.

b) Company’s employee norms.

c) Weather report.

d) Processes of production.

Form, Storm, Norm, and Perform are the phases most of the team goes through. At first a team forms then it breaks up again it normalizes and then they start performing.

41. Which of the following is true about QFD (Quality function Deployment)?

a) This is a process of deploying skilled labour in a project.

b) This is the process for final quality assessment of a product.

c) This is the method capability assurance of any process.

d) This is the process of planning for products and services.

Quality Function Deployment is the process of planning for any product or service according to the customer's need. Here the voice of the customer is prioritized first.

42. What is a Hypothesis test?

a) This a test of product for confirming that the final output is as per requirement.

b) This is a test for hypothecation of companies.

c) This a test of method efficiency and effects

d) None of the above.

Hypothesis test is the test of different methods which shows the better one or the worst one. The hypothesis test results in Null Hypothesis or Alternative Hypothesis.

43. What is TRIZ Method?

a) This is the method of calculating the risk factors of a process.

b) This method is used for calculating failure chances of a process.

c) This is a problem solving method.

d) This is the method of opportunity creation.

TRIZ is the Russian method of problem solving.this method has been now accepted widely for its extensive invention and various aspects.

44. What do you understand by cellular manufacturing in six sigma?

a) Manufacturing product over requirement is called cellular manufacturing.

b) A smaller task within a larger task of manufacturing is known as cellular manufacturing.

c) Failure of an approved manufacturing process.

d) None of the above.

Cellular Manufacturing is known as the most important method of process improvement. Completing a subtask within the main task of manufacturing with flexibility is the characteristic of this.

45. Which of the following statement is correct about Project Charter.

a) This is the full information book of a project.

b) This is the balanced sheet of any company.

c) This is the estimated cost table of any project.

d) This is the chartered accounts report for a project.

Project Charter is the full information sheet of amy project, which includes perspectives, impacts, benefits, and losses.

46. What is the main objective of the Kano Model?

a) To present the model of a new process.

b) To satisfy the work schedule of any company.

c) To help a team for satisfying the customer's need.

d) All of the above.

The Kano Model is made to help a team to fulfill the three stage need of customer by the voice of customer.

47._________ is used for large number of samples.

a) Pareto chart

b) Z score Table

c) P Score Table.

d) Count Chart.

Z score table is used for large number of samples, even this is used in hypothesis

48. What do you understand by Mura in six sigma?

a) Mura is known as the raw materials.

b) Mura is the name of a product.

c) Mura is the term of waste.

d) Mura is the term of unused elements.

MURA is a japanese word, it generally means inconsistency and it is a part of waste.

49. Which among the following facts is/are true about Ordinal Scale?

a) This a measurement scale listing names in order.

b) This is the opposite of Nominal scale

c) Both of the above

d) None of the above.

Ordinal scale is a data, which arranged by numbers or symbols in order.

50. Sort, Straighten, Shine, Standardize, Sustain. These are known in six sigmas as :

a) The Step of Sustain.

b) The S Factor.

c) The 5S

d) None.

The 5S objective is a Japanese method of just in time manufacturing, now it used worldwide.

Find a course provider to learn Six Sigma

Java training | J2EE training | J2EE Jboss training | Apache JMeter trainingTake the next step towards your professional goals in Six Sigma

Don't hesitate to talk with our course advisor right now

Receive a call

Contact NowMake a call

+1-732-338-7323Enroll for the next batch

Six Sigma Online Training Classes

- Dec 8 2025

- Online

Six Sigma Online Training Classes

- Dec 9 2025

- Online

Six Sigma Online Training Classes

- Dec 10 2025

- Online

Six Sigma Online Training Classes

- Dec 11 2025

- Online

Six Sigma Online Training Classes

- Dec 12 2025

- Online

Related blogs on Six Sigma to learn more

Top 50 Six Sigma Black Belt Certification Exam Questions and Answers

The IASSC Lean Six Sigma Black Belt™ (ICBB™) certification will give you proficiency in lean six sigma methods of DMAIC. We have a collection of Six Sigma Black Belt Certification question and answers for you to quickly take a recap of your learning

Top 60 Six Sigma Green Belt Test Questions and Answers for Practice

Six Sigma Green Belt Certification Questions and Answers in 2025:1. Which of the following is the key benefit of multi-vari charting?It keeps track of the time when measurements were madeIt graphically displays the variation in a processIt assists in

Latest blogs on technology to explore

From Student to AI Pro: What Does Prompt Engineering Entail and How Do You Start?

Explore the growing field of prompt engineering, a vital skill for AI enthusiasts. Learn how to craft optimized prompts for tools like ChatGPT and Gemini, and discover the career opportunities and skills needed to succeed in this fast-evolving indust

How Security Classification Guides Strengthen Data Protection in Modern Cybersecurity

A Security Classification Guide (SCG) defines data protection standards, ensuring sensitive information is handled securely across all levels. By outlining confidentiality, access controls, and declassification procedures, SCGs strengthen cybersecuri

Artificial Intelligence – A Growing Field of Study for Modern Learners

Artificial Intelligence is becoming a top study choice due to high job demand and future scope. This blog explains key subjects, career opportunities, and a simple AI study roadmap to help beginners start learning and build a strong career in the AI

Java in 2026: Why This ‘Old’ Language Is Still Your Golden Ticket to a Tech Career (And Where to Learn It!

Think Java is old news? Think again! 90% of Fortune 500 companies (yes, including Google, Amazon, and Netflix) run on Java (Oracle, 2025). From Android apps to banking systems, Java is the backbone of tech—and Sulekha IT Services is your fast track t

From Student to AI Pro: What Does Prompt Engineering Entail and How Do You Start?

Learn what prompt engineering is, why it matters, and how students and professionals can start mastering AI tools like ChatGPT, Gemini, and Copilot.

Cyber Security in 2025: The Golden Ticket to a Future-Proof Career

Cyber security jobs are growing 35% faster than any other tech field (U.S. Bureau of Labor Statistics, 2024)—and the average salary is $100,000+ per year! In a world where data breaches cost businesses $4.45 million on average (IBM, 2024), cyber secu

SAP SD in 2025: Your Ticket to a High-Flying IT Career

In the fast-paced world of IT and enterprise software, SAP SD (Sales and Distribution) is the secret sauce that keeps businesses running smoothly. Whether it’s managing customer orders, pricing, shipping, or billing, SAP SD is the backbone of sales o

SAP FICO in 2025: Salary, Jobs & How to Get Certified

AP FICO professionals earn $90,000–$130,000/year in the USA and Canada—and demand is skyrocketing! If you’re eyeing a future-proof IT career, SAP FICO (Financial Accounting & Controlling) is your golden ticket. But where do you start? Sulekha IT Serv

Train Like an AI Engineer: The Smartest Career Move You’ll Make This Year!

Why AI Engineering Is the Hottest Skillset Right Now From self-driving cars to chatbots that sound eerily human, Artificial Intelligence is no longer science fiction — it’s the backbone of modern tech. And guess what? Companies across the USA and Can

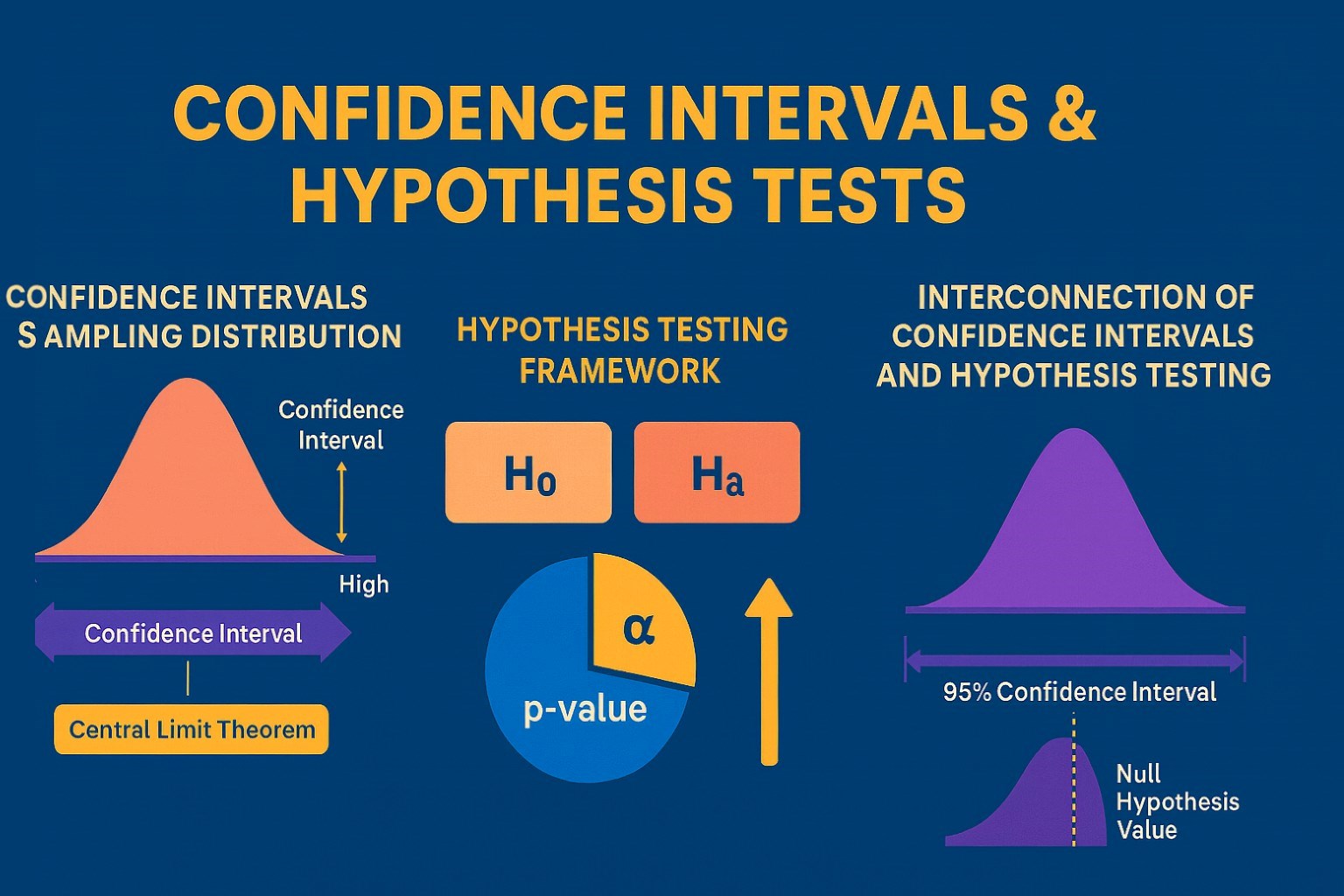

Confidence Intervals & Hypothesis Tests: The Data Science Path to Generalization

Learn how confidence intervals and hypothesis tests turn sample data into reliable population insights in data science. Understand CLT, p-values, and significance to generalize results, quantify uncertainty, and make evidence-based decisions.