Top 50 Six Sigma Black Belt Certification Exam Questions and Answers

(Six Sigma is a group of techniques and tools employed for process improvement. It aims at improving the overall quality by measuring the defects present within a process and eliminating those via a systematic approach.)

The IASSC Lean Six Sigma Black Belt™ (ICBB™) certification will give you proficiency in lean six sigma methods of DMAIC. We have a collection of Six Sigma Black Belt Certification question and answers for you to quickly take a recap of your learning and test your knowledge. These Black Belt question and answers will help to gain confidence to appear for the certification exam. Take advantage of these samples to practice certification test for passing score.

1. What does P stand in the acronym of a process map, SIPOC. What does the P stand for in this acronym?

- Process

- Product

- Population

- Preliminary

A SIPOC is a high-end management tool that simplifies variables into five segments. S-Suppliers; I-inputs; P-process; O-output; C customers

--------------------------------------------------------------------------------------------------------------------------------

2. A Black Belt practitioner constructs a control chart to display a process mean and its outer limits. In the chart above, what does LCL stand for?

- Lower cycle limit

- Lower cycle length

- Lower control limit

- Lower control length

A lower control limit (LCL) represents a downward 3x sigma deviation from the mean value of a variable.

--------------------------------------------------------------------------------------------------------------------------------

3. Which of the control charts must have at least 20 subgroups of observed values to judge whether a process is in control or not?

- R-Chart

- P-Chart

- C-Chart

- Y-Chart

An R-chart contains data gathered at regular intervals. It measures the sample range over time which is a measure of dispersion. The R-chart must have at least 20 subgroups of observed values with each subgroup containing 3 to 6 observations. With these minimum number of observations, it is convenient to observe whether the variation falls within the upper and lower control limits.

-----------------------------------------------------------------------------------------------------------------------------

4.The practice of using specific points in its storage area to indicate when products need to be ordered.

- Kanban

- Poka-yoke

- Checkpoints

- Hoshin

Kanban technique is used in lean. It is a pull technique which eliminates labor and inventory waste. The word Kanban is a Japanese word which means a “signal card”.

---------------------------------------------------------------------------------------------------------------------

5. A Black Belt practitioner is hired to identify a number of Critical to Price (CTP) factors in an effort to streamline and reduce costs associated with manufacturing Product A. The following are CTP factors EXCEPT:

- Component costs

- Assembly costs

- Shipping costs

- Loan refinancing costs

A Critical to Price (CTP) is all the factors influencing the costs of a process. To manufacture a product component costs, assembly costs, shipping costs have to be included to calculate the total cost of manufacturing of the product.

-----------------------------------------------------------------------------------------------------------------------------

6. An advanced quantitative analysis to optimize business or industrial processes through process mapping and modelling using multiple variables. This tool is referred as

- Capability-requirements analysis

- FMEA analysis

- Capability-complexity analysis

- C&E Analysis

The capability and complexity analysis in six sigma helps to define, measure and control of complexity of products and services along with their capabilities. The advanced capability-complexity analysis permits what if analysis to optimize process mapping and modelling using multi-variables.

-------------------------------------------------------------------------------------------------------------------------------------

7. Which of the following techniques dramatically shortens changeover times?

- Continuous flow

- Standard work

- Work in process (WIP)

- Single minute exchange of dies (SMED)

Single-Minute Exchange of Dies (SMED) is a cluster of techniques for dramatically shortening the time to complete a changeover. Shigeo Shingo, a Japanese industrial engineer, first conceptualized SMED whose pioneering work reduced changeover times by a factor of 20 across a wide range of manufacturing companies.

----------------------------------------------------------------------------------------------------------------------------------

8. Correction, over-production, inventory, and motion are all examples of

- Waste

- 5S target areas

- Noise

- Value-added activities

A waste is a non-value added loss. Ideally a project should remove or minimize waste as much as possible before the closure of the project.

-------------------------------------------------------------------------------------------------------------------------------------

9. If the primary metric of a project is reduced cost, then the consequential metric would be?

1 Reduced cycle time

2. Reduced scrap rate

3. Reduced set-up time

4. All the above

5. None of the above

Reduced cycle time, scrap time, set-up time are all the consequential metrics.

-------------------------------------------------------------------------------------------------------------------------------------

10. A company has installed a system that prevents orders with incorrect information from being forwarded to production scheduling. This is an example of which of the following lean tools?

1. Standard work

2. Kanban

3. Poka-Yoke

4. Visual factory

A Poka-Yoke is a Japanese technique which means mistake proofing. It helps the mistakes from not being passed on to next operation.

-----------------------------------------------------------------------------------------------------------------------------

11. Which of the following is a component of a visual factory?

- Product specifications

- Zero defect policies

- Just-in-time policies

- Equipment service manuals

The objective of visual factory is easy visualization of all the activities in the organization. The Visual factory removes the overhead waste by using a combination of signs, charts, dashboards, etc to speed up the transmission of data and information. Product specification, Safety information, Process measures, and work instruction are some components of visual factory. This is used in lean production environment.

-------------------------------------------------------------------------------------------------------------------------------

12. Which of the following tools can be used to identify waste or non-value-added activities?

- Force yield analysis

- Pareto analysis

- Scatter diagram

- Process map

A process map is a detailed pictorial depiction of process flow using color coded symbols to display methodically steps, events and operations. This tool is helps in establishing relationship between inputs and outputs. All those who contribute to the process will document in the process map. This tool is very effective in identifying waste and non-value added activities.

-------------------------------------------------------------------------------------------------------------------------------------

13. The expected value is very close to the term

1. Probabilistic model

2 mean

3. Markov value

4. Regressive value

The term expected value is used for random variables and is very close to the term “mean”

----------------------------------------------------------------------------------------------------------------------------

14. A measurement system analysis is designed to assess the statistical properties of

- Gage variation

- Process performance

- Process stability

- Engineering tolerances

Measurement system analysis (MSA) is a mathematical method to determine the variation within the measurement process which contributes to the overall process variability.

--------------------------------------------------------------------------------------------------------------------------------

15. A system that delivers products or services at the correct time and in the correct quantities is referred to asv

- Takt time

- Kaizen

- Just-in-time

- Single-piece flow

Just in time believes in the elimination of waste. The principle of JIT is to produce the necessary products, at the necessary time and in necessary quantity.

-------------------------------------------------------------------------------------------------------------------------------

16. Which tool is used to assess the significance of factors in either a fractional or a full-factorial experiment structure?

- Analysis of variance (ANOVA)

- Fault tree analysis (FTA)

- Failure mode and effects analysis (FMEA)

- Evolutionary operation (EVOP)

Analysis of variance (ANOVA) is used to test general differences among means. This test is used to assess the fractional or full factorial structures.

------------------------------------------------------------------------------------------------------------------------------

17. Which of the following is defined as continuous, incremental improvement?

- Kanban

- Kaizen

- JIT

- Kaikaku

Kaizen is a long-term approach to work systematically to achieve small incremental continuous improvement in the process to achieve quality and efficiency.

------------------------------------------------------------------------------------------------------------------------------

18. Which one of the following is an inventive methodology for problem-solving?

- BPR

- TPM

- TRIZ

- BMP

TRIZ is an inventive methodology and tool used in problem-solving. TRIZ uses failure analysis such as the reasons for an explosion in a food plant to problem-solve in the future. This methodology also uses systems’ analysis whereby systems and processes are studied in depth in order to find innovative solutions to problems.

------------------------------------------------------------------------------------------------------------------------------

19. Which of the following methods is used to develop an exhaustive list of ideas about a subject?

- Benchmarking

- Brainstorming

- Goal-setting

- Problem-solving

Brainstorming is a technique which is most useful to get an exhaustive list of ideas from a group. In six sigma Brainstorming technique is useful define stage.

-------------------------------------------------------------------------------------------------------------------------------

20. Design for Test is a design technique that offers a benefit of:

- Customer satisfaction tests

- Defect diagnosis

- Manufacturability

- Smaller process variation

Design for test is a technique, which introduces a testing capability in the manufacture of electronics. The objective of this technique is to introduce and validate the capability of diagnosing product defects.

--------------------------------------------------------------------------------------------------------------------------------

21. What is useful to capture the Voice of the Customer (VOC) data from a large sample of the target customer base?

- Government records

- Surveys and questionnaires

- Census data

- Case studies

Data collection is crucial to obtain information about an organization’s target customer base. Business professionals can capture the voice of their customers, by using surveys and questionnaires. This information captured is about their attitudes, preferences, demographics, and purchasing habits. The objective of using surveys and questionnaires is to gather up-to-date information about customer requirements.

--------------------------------------------------------------------------------------------------------------------------------

22. In the coefficient of variation formula below, what does the (S) stand for?

- Sigma

- Standard deviation

- Sum of squares

- Sum of rectangles

The Coefficient of Variation measures the relative variation in a data set and is always shown as a percentage. The standard deviation of a dataset is divided by the mean which shows a variation relative to the mean of the dataset. This type of statistic can be used to measure the variation of two data sets; for example, the dimensions of pencils produced by two machines can be compared in terms of variation to gauge their precision.

--------------------------------------------------------------------------------------------------------------------------------

23. A company wishes to compare the expected mileage of eight different types of car tires. Which of the following statistical tests is best suited for the analysis?

- Multiple regression

- ANOVA

- Paired-difference test

- Z-test

Analysis of Variance (ANOVA) is a statistical test that evaluates the differences among means of three or more samples. In the above-mentioned example, each of the eight-car tires will be tested and its average expected mileage is recorded. The ANOVA analysis substantiates if at least 2 of the tires have significantly different mileages.

--------------------------------------------------------------------------------------------------------------------------------

24. SMED is a lean manufacturing concept that is used to reduce waste in the manufacturing process. What does the E stand for?

- Exchange

- Error

- Estimate

- Expected

"Single Minute Exchange of Die" (SMED) is a lean production concept designed to reduce waste in manufacturing processes. The goal of SMED is to increase the efficiency of converting production from one product to another. This increase in efficiency is done by improving the flow of resources through the production line and decreasing production lot sizes.

--------------------------------------------------------------------------------------------------------------------------------

25. The following are components of Operational Excellence in manufacturing EXCEPT:

- Focusing on the needs of the customers

- Introducing multiple layers of middle management

- Optimizing current activities

- Providing employees with continuous training

Operational Excellence is a management philosophy that emphasizes the roles of leadership and problem-solving in the continuous improvement of an organization. This philosophy is designed to empower employees rather than introducing multiple layers of middle management while focusing on the needs of the customers. The goal of the philosophy is to also optimize current activities and processes and provide employees with continuous training.

--------------------------------------------------------------------------------------------------------------------------------

26. Which one of the following modes are ideal for informal communication?

- Water-cooler discussion

- Presentation

- Group meeting

Informal communication in an organization serves a number of purposes such as providing quick updates, offering support to employees in a deadline crunch, and addressing minor delays and complications. Informal communication that occurs in an organization such as a quick chat by the water-cooler can serve these purposes. Face-to-face meetings can also be informal depending on the nature of the discussion and its goals.

--------------------------------------------------------------------------------------------------------------------------------

27. Positional, cyclical, and temporal variations are most commonly analyzed in

- SPC charts

- Multi-vari charts

- Cause and effect diagrams

- Run charts

A multi-vary chart graphically depicts the variation pattern. The positional, cyclical and temporal variations are analyzed by multi-vari charts.

--------------------------------------------------------------------------------------------------------------------------------

28. Which of the following is an important responsibility of a project champion?

- Leading the team

- Documenting the overall progress of the team

- Allocating resources to support the team

- Coaching the team in DMAIC process

A project champion should support his team for project completion. He should allocate resources to support the team.

--------------------------------------------------------------------------------------------------------------------------------

29. Which of the following tools is appropriate to use with multiple criteria requiring a single option to be selected?

(A) Pugh matrix

(B) Kano model

(C) Hypothesis testing

(D) PDCA

A Pugh matrix is used to evaluate many concepts based on their strengths and weakness against to a reference concept. The reference concept is also called datum or base concept.

--------------------------------------------------------------------------------------------------------------------------------

30. When the variation cause is a cluttered workstation which technique helps to increase the process stability?

- 5S

- SMED

- Preventive maintenance

- Visual factory

In six sigma, a 5S can be used to reduce waste. A 5S in lean sigma ensures smart and clean workstation organization. This helps to increase the process stability.

--------------------------------------------------------------------------------------------------------------------------------

31. The process developing a problem statement by a six sigma team will help to

- Agree on key dates associated with completing major project phases

- Achieve consensus and ownership of the process

- Determine solutions

- Determine how often it should meet.

A problem statement is a precise description of an issue. A problem statement helps to get a consensus to understand the issue or the problem and the team members can take ownership of the process.

--------------------------------------------------------------------------------------------------------------------------------

32. Which of the following will have the most influence on consumers’ perception of quality?

(A) Industry standards

(B) Company financial performance

(C) Audit results

(D) Service and repair policies

Quality usually means exceeding customer expectations. The service and repair policies after the purchase of the product will enhance the customer experience and his exception on quality.

--------------------------------------------------------------------------------------------------------------------------------

33. Which of the following is the correct formula for DPMO?

- D/TOP

- DPO×1,000,000

- D×U×OP

- DPU/DPO

Defects per million opportunities (DPMO) is a measure of process performance in lean six sigma.

DPMO is the ratio between the number of defects and number of opportunities multiplied by one million.

--------------------------------------------------------------------------------------------------------------------------------

34. An important aspect of data collection is that the data collector should

- Determine the dispersion of the data

- Know how the data are to be used

- Use a control chart to analyze the data

- Use stratified sampling plan

Data collection is a systematic method of gathering the data from many sources to get an accurate information of the desired area of interest. The most important aspect of any statistician is to know where to get the data and how to use that data to get the desired output.

--------------------------------------------------------------------------------------------------------------------------------

35. A change agent is responsible for helping the organization do which of the following?

- Overcome fear of the unknown

- Reorganize departments

- Determine performance criteria

- Identify which group is responsible for the change

A change agent is a typical interchanged word used for the black belt. Change is difficult and ambiguous. The change agent helps to overcome the fear of the unknown in organizations.

--------------------------------------------------------------------------------------------------------------------------------

36. A method that changes data without significantly reducing accuracy or precision is known as

(A) Bias adjustment

(B) Statistical efficiency

(C) Blocking

(D) Coding

Coding is a process of classifying and categorizing the qualitative and quantitative data for analysis. Coding process does not reduce the accuracy or precision.

--------------------------------------------------------------------------------------------------------------------------------

37. Which of the following best describes a team that has members with different skills or roles from different areas within the organization?

(A) Self-directed

(B) Cross-functional

(C) Parallel

(D) Process

A cross-functional team is a group of people with different functional skill sets who work towards a common organizational objective.

--------------------------------------------------------------------------------------------------------------------------------

38. In measurement system analysis, which of the following pairs of data measures is used to determine total variance?

- Process variance and reproducibility

- Noise system and repeatability

- Measurement variance and process variance

- System variance and bias

MSA is a tool to determine the amount of variation by the measurement system. Measurement variance and process variance tools are used to minimize the measurement system variation.

--------------------------------------------------------------------------------------------------------------------------------

39. Correction, over-production, inventory, and motion are all examples of

- Waste

- 5S target areas

- Noise

- Value-added activities

A waste is an action which is not required to carry out a process. They are non-value adding to complete a process successfully. Correction, over-production, inventory, and motion are all non-value adding wastes.

--------------------------------------------------------------------------------------------------------------------------------

40. When the sampling method used creates a difference between the result obtained from the sample and the actual population value, the difference is known as

- Correlation

- Precision

- Accuracy

- Bias

In statistics, in sampling method, the difference between the result obtained from the sample and the actual population is termed as bias.

--------------------------------------------------------------------------------------------------------------------------------

41. A team after investigating ways to reduce power outages determined that an outage can occur in only three ways: grid failure, local transformer failure or local overload. After a detailed investigation of these three events for possible causes, etc, they draw a diagram that “fans out” using the power outage as the handle of the fan. Which approach to problem solving best describe these improvements?

1. Affinity diagram

2 Inter-relationship digraph

3. Tree diagram

4. Process decision program chart

A tree diagram begins with a central problem and then branches to many items until the central problem is exhausted. The tree diagram helps the six sigma team to move from a general to specific in a systematic way.

--------------------------------------------------------------------------------------------------------------------------------

42. When a random sample is selected from a population, the mean of the sample is not equal to the mean of the population. This is due to:

- Type I error

- Type II error

- Sampling error

- No exact measurements

A sampling error is caused by the difference between the sample used to estimate the population and the actual population. This error is caused by the observation of the sample instead of the whole population.

--------------------------------------------------------------------------------------------------------------------------------

43. A technique for demonstrating the connection between customer needs and features on the product

- Flow charts and process maps

- Cause and effect diagrams

- Pareto chart

- Relationship matrix

A relationship matrix bridges the gap between what and how. This is a new business development matrix. This matrix helps to establish the relationship between the customer needs and the featuresonthe product.

--------------------------------------------------------------------------------------------------------------------------------

44. SWOT is an acronym for

- Statistics without optimum test

- Strength weakness opportunity and threat

- Sensory Weibull ordinal tools

- Success wields optimal tea

A SWOT analysis is internal and external environment analysis of any organization. Strengths and weakness are internal analysis and opportunities are external environment analysis.

--------------------------------------------------------------------------------------------------------------------------------

45. The quality leader responsible for the term Total Quality Management (TQM):

- Ishikawa

- Crosby

- Feigenbaum

- Taguchi

The concept of TQM was found in1920sapplied for product quality control. This concept was further improvised by Feigenbaum.

--------------------------------------------------------------------------------------------------------------------------------

46. A quality leader associated with the concept of robustness is

- Juran

- Ishikawa

- Crosby

- Taguchi

The robust is the leader associated with robustness.Robustdesign method is also known as Taguchi method improves engineering productivity.

--------------------------------------------------------------------------------------------------------------------------------

47. The causes in cause and effect diagram include

- Man, manufacturing, methods, material

- Marketing, methods, material, machines

- Man, material, millennium, machines

- Man, material, methods, machines

--------------------------------------------------------------------------------------------------------------------------------

48. What is customer segmentation?

- Dividing a particular customer into parts that are more easily understood

- Grouping customers by one or more criteria

- Maintaining secure customer listings to minimize communication among them

- Eliminating or “cutting off” customers with poor credit history

Customer segmentation is a process of dividing the customer base into groups based on some common criteria.

-----------------------------------------------------------------------------------------------------------------------------

49. The activity of a project not on the critical path requires 20% more time than originally allocated. The project team should

- Inform all concerned that the entire project will be delayed by 20%

- Inform all concerned that the entire project will be delayed but by less than 20%

- Study the effect this will have on other activities because the project may still be on schedule

- Inform all the concerned that this effect may not have impact on other activities.

A critical path method (CPM) is an algorithm used to schedule activities for a project. This analysis works in conjunction with project evaluation and review technique (PERT).

--------------------------------------------------------------------------------------------------------------------------------

50. The workers of a manufacturing unit wants to maintain cleanliness on a daily basis. Which approach is most apt?

- 5S

- Poka yoke

- Kaizen

- PDCA

The 5S analysis represents the workplace organization for process improvement. The 5S are Sort, Straighten, Shine, Standardize, and Sustain.

-----------------------------------------------------------------------------------------------------------------------------

Six Sigma Black Belt Exam Details:

Exam Details: https://www.iassc.org/six-sigma-certification/black-belt-certification/

Exam name: IASSC Certified Black Belt Exam

Six Sigma Black Belt Certification Duration: 240 minutes

No. of Six Sigma Black Belt Certification Questions: 150

Six Sigma Black Belt Passing score: 77%

Validated against: https://www.iassc.org/body-of-knowledge/black-belt-body-of-knowledge/

Format: Multiple choice/True-False

Six Sigma Black Belt Certification Exam price: $395 USD

Find a course provider to learn Six Sigma

Java training | J2EE training | J2EE Jboss training | Apache JMeter trainingTake the next step towards your professional goals in Six Sigma

Don't hesitate to talk with our course advisor right now

Receive a call

Contact NowMake a call

+1-732-338-7323Enroll for the next batch

Six Sigma Online Training Classes

- Dec 15 2025

- Online

Six Sigma Online Training Classes

- Dec 16 2025

- Online

Six Sigma Online Training Classes

- Dec 17 2025

- Online

Six Sigma Online Training Classes

- Dec 18 2025

- Online

Six Sigma Online Training Classes

- Dec 19 2025

- Online

Related blogs on Six Sigma to learn more

Six Sigma White Belt Certification Exam Questions and Answers

The six sigma white belt certification will give you knowledge on process improvement, why it is used in businesses globally to eliminate waste. You will take the first step into the world of six sigma and be a part of the process improvement team

Top 60 Six Sigma Green Belt Test Questions and Answers for Practice

Six Sigma Green Belt Certification Questions and Answers in 2025:1. Which of the following is the key benefit of multi-vari charting?It keeps track of the time when measurements were madeIt graphically displays the variation in a processIt assists in

Latest blogs on technology to explore

From Student to AI Pro: What Does Prompt Engineering Entail and How Do You Start?

Explore the growing field of prompt engineering, a vital skill for AI enthusiasts. Learn how to craft optimized prompts for tools like ChatGPT and Gemini, and discover the career opportunities and skills needed to succeed in this fast-evolving indust

How Security Classification Guides Strengthen Data Protection in Modern Cybersecurity

A Security Classification Guide (SCG) defines data protection standards, ensuring sensitive information is handled securely across all levels. By outlining confidentiality, access controls, and declassification procedures, SCGs strengthen cybersecuri

Artificial Intelligence – A Growing Field of Study for Modern Learners

Artificial Intelligence is becoming a top study choice due to high job demand and future scope. This blog explains key subjects, career opportunities, and a simple AI study roadmap to help beginners start learning and build a strong career in the AI

Java in 2026: Why This ‘Old’ Language Is Still Your Golden Ticket to a Tech Career (And Where to Learn It!

Think Java is old news? Think again! 90% of Fortune 500 companies (yes, including Google, Amazon, and Netflix) run on Java (Oracle, 2025). From Android apps to banking systems, Java is the backbone of tech—and Sulekha IT Services is your fast track t

From Student to AI Pro: What Does Prompt Engineering Entail and How Do You Start?

Learn what prompt engineering is, why it matters, and how students and professionals can start mastering AI tools like ChatGPT, Gemini, and Copilot.

Cyber Security in 2025: The Golden Ticket to a Future-Proof Career

Cyber security jobs are growing 35% faster than any other tech field (U.S. Bureau of Labor Statistics, 2024)—and the average salary is $100,000+ per year! In a world where data breaches cost businesses $4.45 million on average (IBM, 2024), cyber secu

SAP SD in 2025: Your Ticket to a High-Flying IT Career

In the fast-paced world of IT and enterprise software, SAP SD (Sales and Distribution) is the secret sauce that keeps businesses running smoothly. Whether it’s managing customer orders, pricing, shipping, or billing, SAP SD is the backbone of sales o

SAP FICO in 2025: Salary, Jobs & How to Get Certified

AP FICO professionals earn $90,000–$130,000/year in the USA and Canada—and demand is skyrocketing! If you’re eyeing a future-proof IT career, SAP FICO (Financial Accounting & Controlling) is your golden ticket. But where do you start? Sulekha IT Serv

Train Like an AI Engineer: The Smartest Career Move You’ll Make This Year!

Why AI Engineering Is the Hottest Skillset Right Now From self-driving cars to chatbots that sound eerily human, Artificial Intelligence is no longer science fiction — it’s the backbone of modern tech. And guess what? Companies across the USA and Can

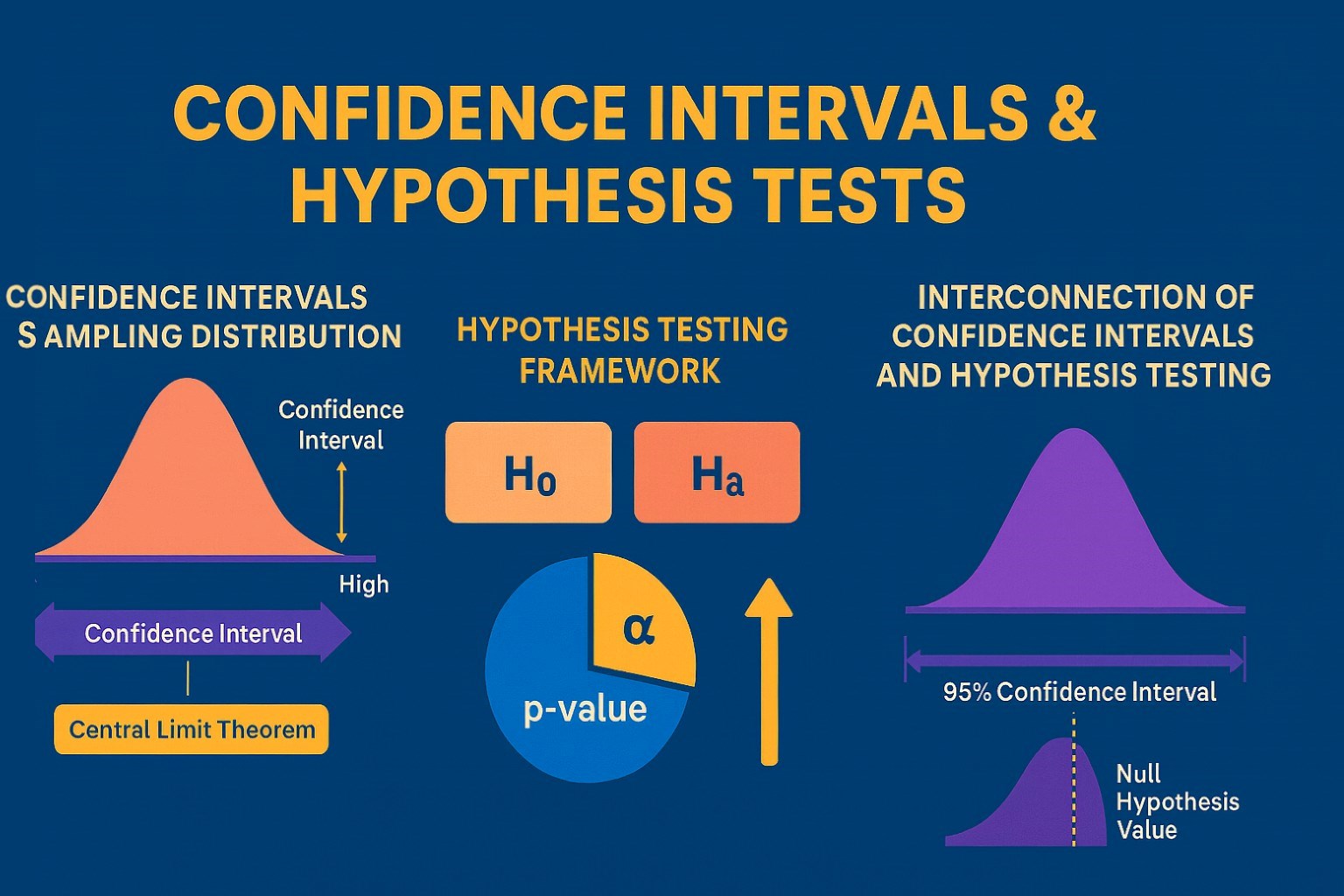

Confidence Intervals & Hypothesis Tests: The Data Science Path to Generalization

Learn how confidence intervals and hypothesis tests turn sample data into reliable population insights in data science. Understand CLT, p-values, and significance to generalize results, quantify uncertainty, and make evidence-based decisions.