What Makes a Quality Engineer Perfect?

The job of a quality engineer is extremely difficult. Primarily dealing with product quality, quality engineers are usually found working in manufacturing plants of various companies. Quality engineers, in conjunction with production staff, suppliers, and departmental managers have the aim of improving product quality, and the end-goal of increased customer satisfaction.

The following are some of the key aspects of quality engineering that quality engineers have to focus on.

Focus on the Customer

Quality engineering means absolutely nothing, if it is not customer-centric in nature. Quality engineers have to regularly monitor feedback and customer reviews to understand the customers’ opinion regarding the company’s products, and what should be improved to cater to the customers better.

Ensuring Improvement

After analyzing customer reviews, quality engineers take various proactive measures such as development and implementation of improvement programs. These measures enhance not just the quality management systems in place, but also the quality of production processes, which rapidly help in putting quality issues to bed.

Creating Documentation and Setting Quality Metrics

Standard implementation is no simple task for quality engineering professionals. Performance measurements need to be developed for effective implementation. The different stages of production have quality metrics set by quality engineers. Quality manuals, procedures, and other documentation are created by them. Requirements for document control and records management are also established by the engineers. The work of quality engineers is generally in tandem with the production staff, in order to train members of the production team about the importance of maintaining quality standards and following quality procedures. The engineers also assist quality inspectors ably in their work.

Interaction with Suppliers

Working with the supply chain is an important aspect of quality engineering. It is required to ensure top quality components, raw materials, and sub-assemblies to be used in the production process. It is the responsibility of quality engineers to ensure effective inspection of incoming raw materials. If there are any faults from the supplier’s side, it’s up to the quality engineers to solve them.

Establishing Quality Standards

Quality is a requisite in the production process, and quality engineering experts are responsible for the establishment and implementation of quality management systems. This is the most effective way to control and measure quality during the production process. Apart from establishing standards for individual products, document standards and process standards for the production team are also established by them. Many quality engineers make independent standards like ISO 9000 foundations for their systems.

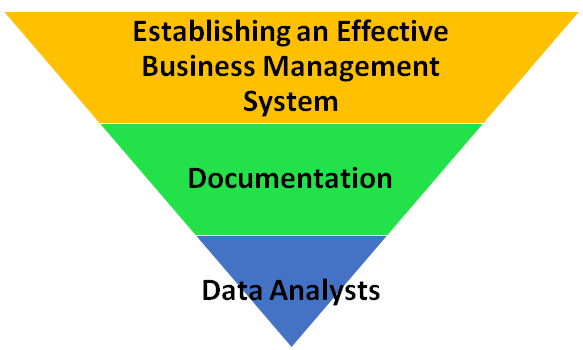

Hallmarks of a Top Quality Engineer

- Establishing an Effective Business Management System: Quality engineers are often judged on how effective their business management systems are. What is a business management system? Quite simply, a business management system ensures timely execution of activities on a daily basis and keeps all strategies moving forward to benefit the business as a whole. Integration of performance metrics is an important part of a top business management system.

- Documentation: The execution of tasks and processes, along with the detection and identification of problems need to be documented, and you can expect quality documentation from the finest quality engineers. Building a value chain is seen as a great skill for quality engineers to have, as up-to-date value chains can benefit all parts of the business. Value chains describe organizational procedure integration, along with the functional metrics of those procedures.

- Data Analysts: A quality engineer who is not a good data analyst would struggle at some point of time in his career. Data analysis emphasizes on the need of prevention, instead of focusing on the cure. Problem identification and problem solving are important. But recurring problems are unwanted, and can be greatly disturbing to workflow. Statistical assessments and data analyses are major parts of identifying both common-cause and special-cause issues, and resolving them appropriately.

With the ever increasing scope and career growth of quality engineers nowadays, there has been a great demand for quality engineering training courses in recent years. Even though the work of a quality engineer is tough, it is thoroughly rewarding for people who manage to cement their positions as top notch quality engineers.

Take the next step towards your professional goals in Quality Engineering

Don't hesitate to talk with our course advisor right now

Receive a call

Contact NowMake a call

+1-732-338-7323Related blogs on Quality Engineering to learn more

How To Become a Successful Quality Engineer?

The Quality engineers, are the also known as quality assurance engineers, take active part in ensuring that the products and, materials in an organization meet the quality standards. They analyze the quality of performance, using analytical and stati

What is Quality Engineering all about?

Quality engineering deals with the development, operation, management, & maintenance of IT systems as well as enterprise architectures with high quality standard.

Latest blogs on technology to explore

Drug Safety & Pharmacovigilance: Your 2026 Career Passport to a Booming Healthcare Industry!

Why This Course Is the Hottest Ticket for Science Grads & Healthcare Pros (No Lab Coat Required!)" The Exploding Demand for Drug Safety Experts "Did you know? The global pharmacovigilance market is set to hit $12.5B by 2026 (Grand View Research, 202

Launch Your Tech Career: Why Mastering AWS Foundation is Your Golden Ticket in 2026

There’s one skill that can open all those doors — Amazon Web Services (AWS) Foundation

Data Science in 2026: The Hottest Skill of the Decade (And How Sulekha IT Services Helps You Master It!)

Data Science: The Career that’s everywhere—and Nowhere Near Slowing Down "From Netflix recommendations to self-driving cars, data science is the secret sauce behind the tech you use every day. And here’s the kicker: The U.S. alone will have 11.5 mill

Salesforce Admin in 2026: The Career Goldmine You Didn’t Know You Needed (And How to Break In!)

The Salesforce Boom: Why Admins Are in Crazy Demand "Did you know? Salesforce is the 1 CRM platform worldwide, used by 150,000+ companies—including giants like Amazon, Coca-Cola, and Spotify (Salesforce, 2025). And here’s the kicker: Every single one

Python Power: Why 2026 Belongs to Coders Who Think in Python

If the past decade was about learning to code, the next one is about coding smarter. And in 2026, the smartest move for any IT enthusiast is learning Python — the language that powers AI models, automates the web, and drives data decisions across ind

The Tableau Revolution of 2025

"In a world drowning in data, companies aren’t just looking for analysts—they’re hunting for storytellers who can turn numbers into decisions. Enter Tableau, the #1 data visualization tool used by 86% of Fortune 500 companies (Tableau, 2024). Whether

From Student to AI Pro: What Does Prompt Engineering Entail and How Do You Start?

Explore the growing field of prompt engineering, a vital skill for AI enthusiasts. Learn how to craft optimized prompts for tools like ChatGPT and Gemini, and discover the career opportunities and skills needed to succeed in this fast-evolving indust

How Security Classification Guides Strengthen Data Protection in Modern Cybersecurity

A Security Classification Guide (SCG) defines data protection standards, ensuring sensitive information is handled securely across all levels. By outlining confidentiality, access controls, and declassification procedures, SCGs strengthen cybersecuri

Artificial Intelligence – A Growing Field of Study for Modern Learners

Artificial Intelligence is becoming a top study choice due to high job demand and future scope. This blog explains key subjects, career opportunities, and a simple AI study roadmap to help beginners start learning and build a strong career in the AI

Java in 2026: Why This ‘Old’ Language Is Still Your Golden Ticket to a Tech Career (And Where to Learn It!

Think Java is old news? Think again! 90% of Fortune 500 companies (yes, including Google, Amazon, and Netflix) run on Java (Oracle, 2025). From Android apps to banking systems, Java is the backbone of tech—and Sulekha IT Services is your fast track t